MTD Instruction Manual: A Comprehensive Guide

This detailed manual offers a step-by-step guide to effortlessly operate your MTD equipment, ensuring optimal performance and longevity for years to come.

MTD Products is a leading global manufacturer of outdoor power equipment, renowned for innovation and durability. This manual serves as your comprehensive resource for understanding and maintaining your MTD machine. From lawnmowers and snow blowers to zero-turn riders and garden tractors, MTD consistently delivers reliable performance.

We pride ourselves on engineering products designed for both residential and professional use. This guide will familiarize you with the core functionalities of your specific MTD model, ensuring safe and efficient operation. Whether you’re a seasoned landscaper or a first-time homeowner, this manual provides the necessary information to maximize your equipment’s lifespan and effectiveness. Explore the features and benefits of your MTD product today!

Understanding Your MTD Equipment

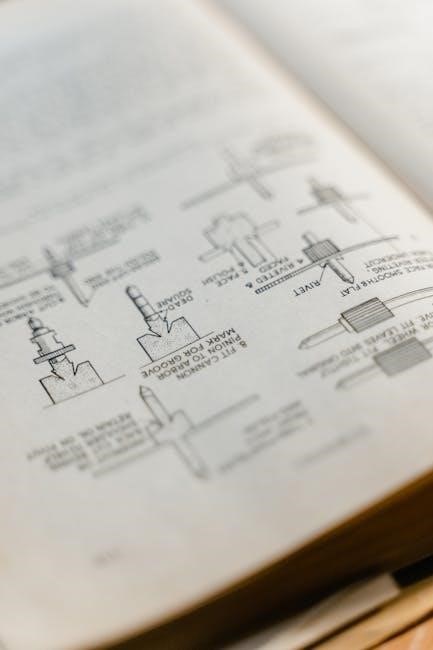

Familiarizing yourself with your MTD equipment is crucial for safe and effective operation. Each model boasts unique features, so carefully review the specific diagrams and descriptions within this manual. Key components include the engine, cutting deck (if applicable), drive system, and control panel.

Understanding the function of each part allows for proper maintenance and troubleshooting. Pay close attention to labeled controls for speed, direction, and attachment engagement. This manual details the location of essential features like the fuel tank, oil dipstick, and safety switches. Proper knowledge of your MTD equipment will enhance your experience and ensure years of reliable service. Refer to the parts diagrams for visual assistance.

Safety Precautions

Prioritizing safety is paramount when operating MTD equipment. Always read and understand all safety warnings and instructions before use. Keep children and pets away from the operating area. Wear appropriate safety gear, including eye protection, sturdy footwear, and hearing protection.

Never operate the equipment while under the influence of drugs or alcohol. Ensure the area is clear of obstacles before starting. Disconnect the spark plug wire before performing any maintenance. Be aware of potential hazards like thrown objects. Familiarize yourself with emergency stop procedures. Following these precautions will minimize the risk of injury and ensure a safe operating experience with your MTD product.

General Safety Rules

Always maintain a safe working environment. Inspect the equipment before each use, checking for loose parts or damage. Never modify the equipment in any way. Keep hands and feet clear of moving parts during operation. Avoid operating on steep slopes or uneven terrain.

Ensure proper ventilation when operating indoors or in enclosed spaces. Never leave the equipment running unattended. Be mindful of bystanders and maintain a safe distance. Store fuel in a properly labeled container, away from heat and open flames. Regularly inspect and maintain safety features, like guards and shields. Adhering to these general rules promotes safe and responsible operation.

Specific Safety Warnings

Rotating blades present a serious hazard; always disconnect the spark plug before performing any maintenance. Never operate the equipment with damaged or missing parts. Be extremely cautious when operating near children or pets. Avoid wearing loose clothing or jewelry that could become entangled.

Never direct any discharge outlet towards people or property. Exercise caution when crossing roads or pathways. Understand the terrain and potential obstacles before operating. Always wear appropriate personal protective equipment, including eye and ear protection. Familiarize yourself with the emergency stop mechanism. Ignoring these specific warnings could result in severe injury.

Assembly Instructions

Before beginning assembly, carefully unpack all components and verify against the parts list to ensure everything is present. A clean, spacious, and well-lit workspace is recommended. Refer to the detailed diagrams for proper component orientation.

Take your time and avoid forcing parts together; gentle pressure is usually sufficient. Ensure all bolts and fasteners are securely tightened, but avoid over-tightening. Double-check all connections before proceeding to the initial setup phase. Proper assembly is crucial for safe and efficient operation of your MTD equipment. Following these instructions will guarantee a smooth and successful build.

Unboxing and Inventory

Carefully open the shipping carton and inspect it for any visible damage incurred during transit. Retain the packaging material until assembly is complete and you’ve verified all parts are accounted for.

Lay out all components on a protected surface, like a drop cloth or cardboard, to prevent scratching. Cross-reference each part with the detailed parts list included in this manual. Note any discrepancies immediately and contact customer support. Document any damage with photographs. A thorough inventory ensures a hassle-free assembly process and prevents delays later on. Confirm quantities and part numbers before proceeding.

Attaching Components

Begin by securely attaching the handle to the main chassis using the provided bolts and washers, ensuring proper alignment. Refer to the diagrams for correct orientation. Next, connect any included attachments, such as side discharge chutes or mulching plugs, following the illustrated steps.

Tighten all fasteners to the manufacturer’s specified torque – do not overtighten! Double-check all connections for stability before proceeding. Proper component attachment is crucial for safe and efficient operation. If encountering resistance, re-examine the instructions and ensure correct part placement. A secure assembly minimizes vibration and maximizes performance.

Initial Setup

Before the first use, carefully inspect all components for any shipping damage. Add the recommended oil type and quantity as specified in the engine section – do not overfill. Check the tire pressure and adjust to the recommended PSI, found on the tire sidewall. Ensure all guards and safety devices are correctly installed and functioning properly.

Familiarize yourself with the location of all controls – throttle, brake, and blade engagement. Perform a brief test run in a safe, open area to confirm proper operation. This initial setup ensures optimal performance and safety. Refer to the parts diagram if any components are missing or damaged.

Operating Instructions

Always review the safety precautions before operation. To start the engine, ensure the blade is disengaged and the parking brake is set. Follow the priming and choke instructions specific to your engine model. Pull the starter cord firmly and smoothly – avoid jerking. Once running, gradually engage the blade and adjust the speed using the throttle control.

Steering is achieved through the handlebar; maintain a firm grip. Be mindful of obstacles and uneven terrain. When finished, disengage the blade, set the parking brake, and allow the engine to cool before storing; Regular, careful operation extends the life of your MTD equipment.

Starting the Engine

Prior to starting, verify the fuel tank is filled with the correct fuel type and the oil level is adequate. Ensure the blade is fully disengaged and the parking brake is firmly applied. If the engine is cold, engage the choke – consult your specific model’s diagram for location. Prime the engine by pressing the primer bulb several times.

Grasp the starter handle firmly and pull the cord with a smooth, controlled motion. Avoid rapid jerking, which can damage the starter mechanism. Once the engine starts, gradually disengage the choke. Allow the engine to warm up briefly before engaging any attachments or beginning operation.

Controlling Speed and Direction

Your MTD equipment’s speed is typically controlled via a lever or pedal, offering variable settings to match the terrain and task. Familiarize yourself with the control’s full range of motion before operation. Directional control is usually managed by a steering wheel or handle bars; apply gentle pressure for smooth turns.

Avoid abrupt changes in speed or direction, especially on slopes or uneven ground, to maintain stability and prevent loss of control. Always keep a firm grip on the steering mechanism. Be mindful of obstacles and pedestrians in your operating area; Practice in a clear, open space to gain confidence with the controls.

Using Attachments

MTD equipment often boasts versatility through compatible attachments, expanding its functionality beyond basic operation. Before attaching any implement, always ensure the engine is off and the equipment is completely stationary. Consult the attachment’s specific manual for detailed installation instructions – never force a connection.

Verify the attachment is securely locked into place before resuming operation. Adjust operating parameters, like speed and engagement settings, as recommended by the attachment’s guide. Regularly inspect attachments for wear and tear, and replace damaged components promptly. Improper attachment use can lead to equipment damage or personal injury.

Maintenance and Care

Consistent maintenance is crucial for extending the life and ensuring the reliable performance of your MTD equipment. Regular checks and servicing prevent costly repairs and maintain optimal functionality. This section details a routine maintenance schedule, covering everything from visual inspections to fluid level checks.

Adhering to this schedule, alongside performing necessary procedures like oil changes and blade maintenance, will significantly impact your equipment’s longevity. Always disconnect the spark plug before performing any maintenance. Refer to the specific sections for detailed instructions on each procedure, prioritizing safety and proper technique.

Routine Maintenance Schedule

To guarantee peak performance, follow this schedule diligently. After each use, inspect for loose fasteners and debris. Monthly, check and clean the air filter, ensuring proper airflow to the engine. Every 25 hours of operation (or seasonally), change the engine oil – using the manufacturer’s recommended grade.

Inspect the drive belt for wear and tear, replacing as needed. Annually, sharpen or replace the blades, and lubricate all moving parts. Always refer to the full manual for specific model recommendations. Maintaining this schedule prevents breakdowns and ensures years of reliable service from your MTD equipment.

Oil Change Procedures

Regular oil changes are crucial for engine health. First, warm the engine slightly for easier draining. Locate the oil drain plug and position a suitable container underneath. Carefully remove the plug, allowing the old oil to drain completely. Replace the drain plug securely.

Next, remove the oil fill cap and add the recommended oil type and quantity (refer to your model’s specifications). Check the oil level with the dipstick, ensuring it’s within the marked range. Dispose of used oil responsibly at a designated recycling center. This simple procedure extends engine life and maintains optimal performance.

Blade Sharpening and Replacement

Maintaining sharp blades ensures a clean cut and efficient operation. To sharpen, disconnect the spark plug wire for safety! Secure the blade and use a metal file or grinding wheel to restore the cutting edge, maintaining the original angle. Always wear safety glasses.

For replacement, carefully remove the old blade using appropriate wrenches, noting its orientation. Install the new blade, ensuring it’s correctly positioned and tightened to the manufacturer’s specified torque. A dull or damaged blade strains the engine and compromises cutting quality. Regular inspection and maintenance are key for safety and performance.

Troubleshooting Common Issues

Encountering problems? This section addresses frequent concerns. If the engine won’t start, check the fuel level, spark plug connection, and ensure the safety interlocks are engaged correctly. Difficulty with movement often indicates a clogged drive system or a loose belt – inspect and clear debris or adjust tension.

Unusual noises could signal a loose component, a worn bearing, or blade imbalance. Immediately stop the machine and investigate. Refer to the parts diagram for identification. Always disconnect the spark plug before any inspection or repair. Prioritize safety and consult a qualified technician if issues persist.

Engine Won’t Start

If your MTD engine fails to start, systematically check several key areas. First, verify sufficient fuel in the tank and that the fuel shut-off valve (if equipped) is open. Next, inspect the spark plug – ensure it’s clean, properly gapped, and securely connected. Confirm the spark plug wire is firmly attached.

Also, examine the safety interlocks – the operator presence control (OPC) must be fully engaged. A flooded engine can also prevent starting; allow time for fuel to evaporate. If problems continue, consult the detailed diagrams for component locations and consider professional assistance.

Difficulty with Movement

Experiencing trouble with your MTD equipment’s movement? Begin by checking the drive system engagement lever – ensure it’s fully engaged for self-propelled models. Inspect the wheels for obstructions like debris or tightly packed grass. Verify tire pressure is adequate, as low pressure hinders movement.

For hydrostatic transmissions, check the fluid level. A low fluid level can cause sluggishness. Examine the drive belt for wear or breakage; a damaged belt will significantly impact performance. If the issue persists, consult the parts diagrams to locate and inspect the relevant components for proper function.

Unusual Noises

Hearing strange sounds during operation? First, immediately stop the engine and disconnect the spark plug wire for safety. Identify the type of noise – is it a squeal, grinding, or clunking? A squealing sound often indicates a loose or worn belt. Grinding noises may point to bearing issues within the transmission or engine.

Clunking sounds could signify a loose component or a problem with the blade attachment. Carefully inspect all bolts and fasteners, tightening as needed. Refer to the parts diagrams to pinpoint the source of the noise and determine if replacement is necessary. Ignoring unusual noises can lead to further damage.

Parts Diagrams and Identification

Locating replacement parts for your MTD equipment is simplified with detailed diagrams. These illustrations break down the machine into individual components, clearly labeling each part with a unique identification number. Understanding these part numbers is crucial when ordering replacements, ensuring you receive the correct component for your specific model.

Refer to the diagrams in the back of this manual, or access interactive versions online via the MTD website. Each diagram corresponds to a specific system – engine, deck, transmission, etc. – making it easy to find what you need. Always double-check the model number before ordering to guarantee compatibility.

Locating Parts

Finding the correct replacement parts begins with identifying your MTD model number. This number is typically found on a decal affixed to the machine’s frame, often near the engine or under the operator’s platform. Once you have the model number, consult the parts diagrams within this manual or utilize the interactive parts finder on the official MTD website.

The diagrams are organized by system – engine, deck, wheels, and so on – allowing for targeted searches. Note the specific part number associated with the component you need. Local MTD dealers can also assist in locating parts, providing expert advice and ensuring compatibility with your equipment.

Understanding Part Numbers

MTD part numbers are crucial for ordering the correct replacements. These alphanumeric codes uniquely identify each component, ensuring compatibility with your specific model. A typical MTD part number consists of several digits and letters, often indicating the part’s function and manufacturer.

Always double-check the part number against the parts diagram or your original component before placing an order. Variations in seemingly minor details can lead to incorrect parts being shipped. When contacting a dealer or ordering online, provide the complete part number for accurate fulfillment. Referencing the model number alongside the part number further minimizes errors.

Warranty Information

Your MTD product is protected by a limited warranty against defects in materials and workmanship. This warranty’s duration varies depending on the specific product and component – residential versus commercial use also impacts coverage.

Carefully review the warranty documentation included with your purchase for precise details regarding covered parts, labor, and limitations. Generally, the warranty covers manufacturing defects but excludes wear items or damage resulting from misuse or improper maintenance. To initiate a warranty claim, you’ll typically need proof of purchase and a description of the issue.

Coverage Details

MTD’s warranty typically covers defects in materials and workmanship under normal residential use. This includes components like the engine (subject to manufacturer’s warranty terms), chassis, and certain functional parts.

However, the warranty generally does not cover items subject to normal wear and tear, such as belts, blades, tires, and spark plugs. Damage caused by improper maintenance, accidents, misuse, or alterations voids the warranty. Commercial use often has a reduced warranty period. Specific coverage lengths differ by product line; always consult your product’s warranty statement for precise terms and conditions.

Claim Procedures

To initiate a warranty claim, first, locate your original purchase receipt as proof of date and location of purchase. Contact MTD’s customer service department – phone number and online resources are provided in this manual.

You will likely need to provide the model and serial number of your MTD equipment, along with a detailed description of the defect. MTD may request photos or videos to assess the issue. If approved, you may be directed to an authorized service center for repair or replacement. Retain all documentation related to your claim for your records.

Contact Information and Support

For immediate assistance with your MTD product, our dedicated customer service team is available to help. You can reach us by phone at 1-800-800-6380 during business hours, Monday through Friday, 8 AM to 5 PM Central Time.

Alternatively, explore our comprehensive online resources at www.mtdproducts.com/support. This website features frequently asked questions, troubleshooting guides, parts diagrams, and downloadable manuals. We also offer a live chat option for real-time support. Don’t hesitate to contact us – we are committed to ensuring your satisfaction with your MTD equipment!

Customer Service Numbers

Need to speak with a MTD representative? We offer several convenient ways to connect. For general inquiries and support regarding your MTD product, please call our toll-free number at 1-800-800-6380. Our knowledgeable team is ready to assist you Monday through Friday, from 8:00 AM to 5:00 PM Central Time.

For parts ordering assistance, dial 1-800-288-6423. If you are experiencing issues with a warranty claim, please call 1-800-800-6380 and select the warranty options. Please have your model and serial number readily available when you call to expedite the process. We value your business and are dedicated to providing excellent customer support.

Online Resources

MTD provides a wealth of helpful resources directly on our website! Visit www.mtdproducts.com to access a comprehensive FAQ section, troubleshooting guides, and downloadable manuals for your specific MTD model. You can also register your product online for warranty updates and exclusive offers.

Explore our interactive parts diagrams to easily identify replacement parts. Furthermore, our online support portal offers access to how-to videos demonstrating routine maintenance procedures. Connect with other MTD owners through our community forum to share tips and solutions. We are committed to providing convenient, 24/7 access to the information you need.